Are you a machinist?

The science of flatness

Are you just like I whom scrapping the internet and the cast iron plate?

Have you ever been a machinist?

I’m passionate about creating and building things with my own hands. I spend my free time in my home workshop, tinkering with metal and machines, and bringing my ideas to life.

We’re living on a globe, and clearly, it’s not really flat somehow..

Flatness is a critical aspect of machining, as it can significantly impact the performance, accuracy, and reliability of a part or assembly.

I’ve read and learned a lot about surface flatness and how to achieve precision flatness of around 10um or less. There’s even a field of science dedicated to flatness.

So, why am I doing this?

During the COVID-19 crisis and isolation, we really needed something to learn, relax, spend time, and exercise. I started learning about machining and became a machinist, seeking a break from the monotonous world of coding without ideas.

Overview of flatness (manufacturing)

Flatness is an important geometric condition for workpieces and tools. Flatness is the condition of a surface or derived median plane having all elements in one plane

In the manufacture of precision parts and assemblies, especially where parts will be required to be connected across a surface area in an air-tight or liquid-tight manner, flatness is a critical quality of the manufactured surfaces. Such surfaces are usually machined or ground to achieve the required degree of flatness. Metrology of such a surface can confirm and ensure that the required degree of flatness has been achieved as a key step in a manufacturing processes.

Hand Scraping for flatness

Hand scraping is a traditional metalworking technique used to remove small amounts of material from a surface, typically to achieve a precise fit or to create a smooth finish. It involves using a hand tool, called a scraper, to manually remove metal shavings from a workpiece Some of the benefits of hand scraping include:

- High level of precision and control

- Ability to work with a variety of metals and materials

- Can be used to create complex shapes and surfaces

- Does not require specialized equipment or machinery

Let’s take a look at some guides from Switzerland and France

Swiss and French scrapping guide

Swiss and French scrapping guide  Swiss and French scrapping guide

Swiss and French scrapping guide

Tool shaping and measure

Pull Scrap tool

Pull Scrap tool

Pull Scrap tool

Scrap Tool grinding edges

Scrap Tool grinding edges

Automatic Scraping Tools

An Expensive Biax Automatic Half-Moon pattern

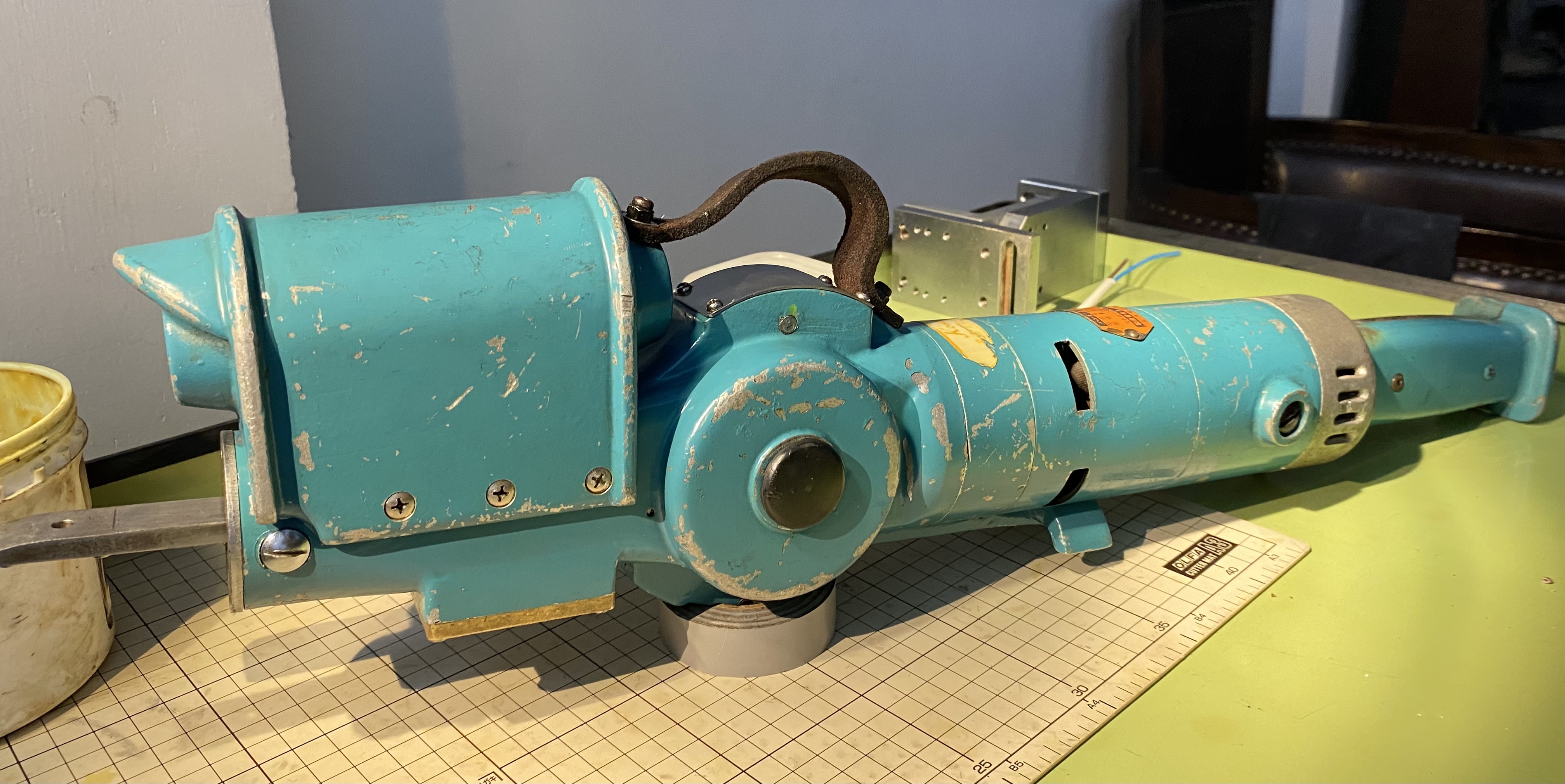

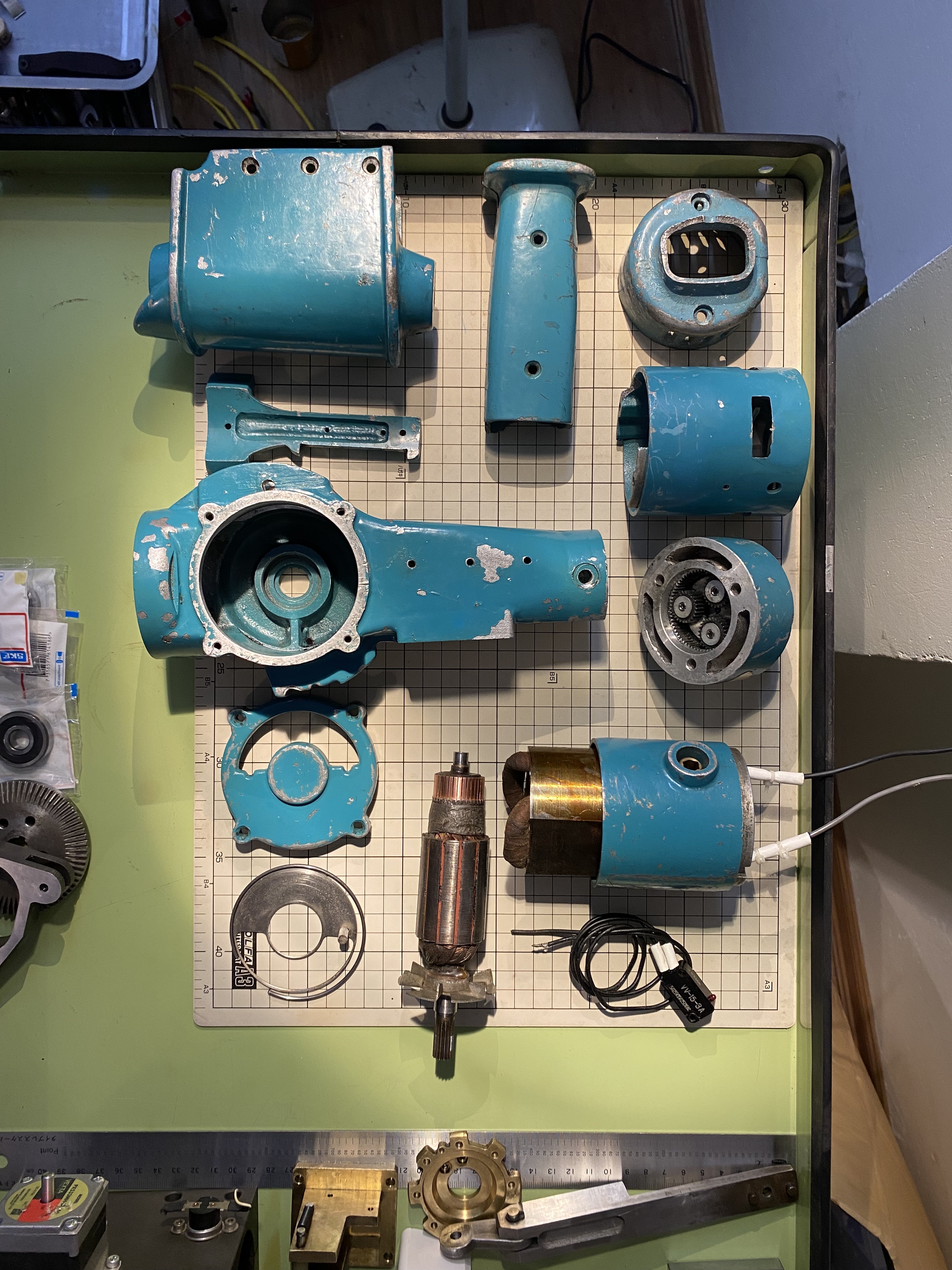

My automatic scrap machine restored

My automatic scrap machine restored

My automatic scrap machine restored

My automatic scrap machine restored

My automatic scrap machine restored

My automatic scrap machine restored

My automatic scrap machine restored

My automatic scrap machine restored

My automatic scrap machine restored

Scrap patterns

Half-Moon

- Half-Moon pattern this is the most hard to archive pattern

Full screen width and center alignment

Full screen width and center alignment

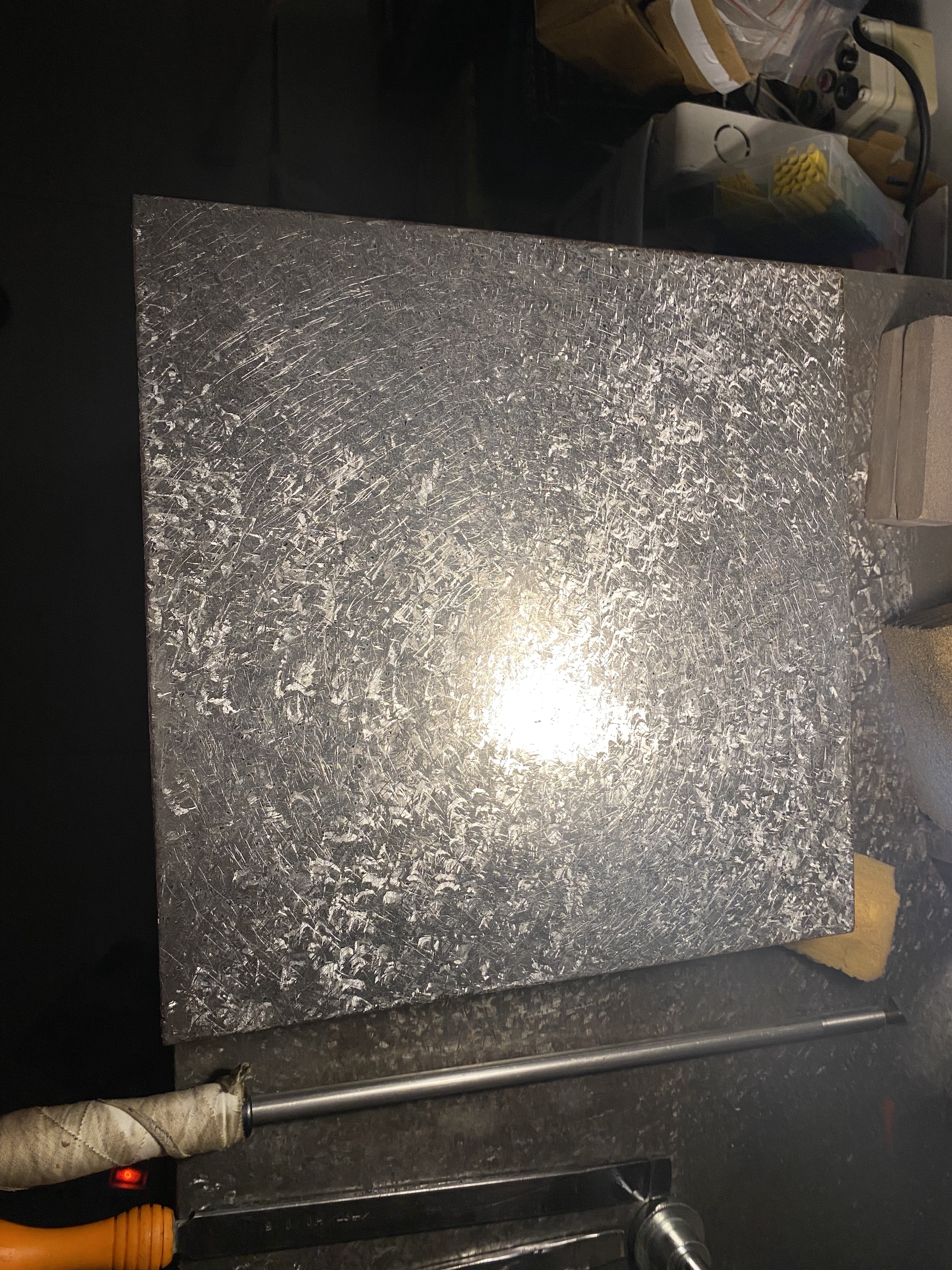

My Half-Moon and Grid Pattern

- It’s very hard to achieve this pattern, but it’s worth it.

Final

- Developing scrapping skills to achieve microns of flatness helps me understand the principles behind precision machine making. Besides, I consider it a ‘hands-on exercise’ and I’ve learned a lot about the precision world and its science. I’m quite confident in making a workable DIY machine that can achieve micron-level precision.

More information from Wiki https://en.wikipedia.org/wiki/Hand_scraper

Are you just like I whom scrapping the internet and the cast iron plate?..